30tons H-Type Power Press Punch High Precision Stamping Punching Machine High Speed Power Press Machine

Production Description Product Parameter Notice of production: In addition to choosing a high manufacturing accuracy, an;

Basic Info

| Model NO. | SAH-30HK |

| Controlling Mode | Artificial |

| Automatic Grade | Manual |

| Power Source | Manual |

| Precision | High Precision |

| Condition | New |

| Model No. | Sah-30HK |

| Color | White or Customized |

| Capacity | 30tons |

| Stroke | 20-30 mm |

| Bed Opening | 500*100 mm |

| Presses Precision | GB(JIS) 1 Class |

| Transport Package | Exporting Packing |

| Specification | Weight: 4~6 tons |

| Trademark | SAMHOOR |

| Origin | China |

| HS Code | 8462490000 |

| Production Capacity | 300sets/Month |

Product Description

Production DescriptionProduct Parameter

| Main Specification | Unit | Parameter | ||

| Capacity | Ton | 30 | ||

| Stroke | mm | 20 | 25 | 30 |

| Stroke Per Minute | S.P.M | 200-100 | 200-900 | 200-800 |

| Die-Hight | mm | 203-233 | 200-230 | 198-228 |

| Slide Adjustment | mm | 30 | ||

| Slide Area | mm | 560*320 | ||

| Bolster Area | mm | 600*450*110 | ||

| Bed Opening | mm | 500*100 | ||

| Main Motor | HP | 10 | ||

| Transfer Mold Motor | HP | 1/4 | ||

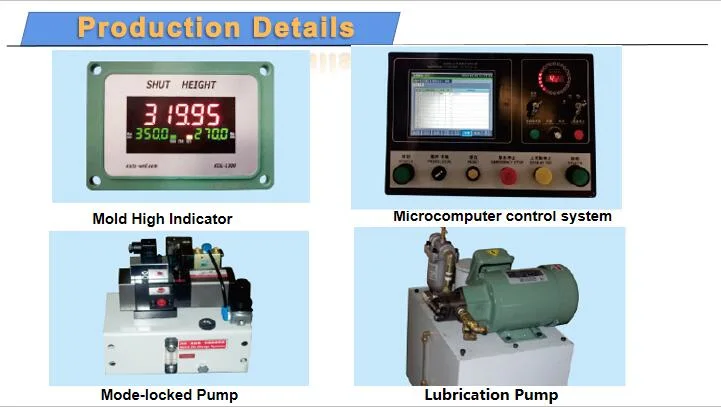

| Lubricating System | Forced Lubrication's system and Cooling machine | |||

| Avoid Shake System | SAHA Prevent Quake Foot | |||

| Presses Dimension | mm | 1200*1370*2220 | ||

| Presses Precision | GB(JIS) 1 Class | |||

Notice of production:

In addition to choosing a high manufacturing accuracy, an reasonable die structure, good heat treatment effect and correct selection of die accuracy, correcting use,maintenance of die are also pretty important links.The following points here should be paid more attention to: 1. The most importing thing is strict and correct using the die equipment.2. Checking the rotating disc and the mounting base of the die on aa regular basis to guarantee the coaxial accuracy of the upper and lower rotating discs.3. After the die install, pls remember to check whether the fastening screw of the installation base of the die is locked correctly.4. If the edge of punch and concave die is worn out, it's ought to stop using and grind in time. Otherwise, the wear degree of the die edge will be expanded rapidly, the wear of the die will be accelerated, and the quality of the high speed stamping machine and the life of the die will be reduced.5. The mould should be put back to the designated position in time after using, and be treated with oil and rust-proof immediately.6. To guarantee the service life of the die, the spring of the die should be replaced regularly, which can greatly to prevent the fatigue damage of the spring from affecting the use of the die.7. Last but not least, no matter whether you use any dies or not at that time, please kindly ensure your own safety.

Where places is suitable for applicating of the heat sink stamping parts?

1.Computer fileds: computer mainboard, PC, IPC, Server, PCTV, Router, Power supply (CPU cooler, VGA cooler, Cooling fan). 2. Machines: Industry/Medical/Auto Spare Parts/Household Appliances etc.3. LED lighting: stage light, high bay light, down light, street light, automobile lamp ,etc.4. Security fields: security cameras, infrared light cameras.5. Home appliances: pico projector, electronic refrigerator, red wine cooler, LASER TV, LCD TV, LED panel, Sound, Air condition, induction cooker, etc.

Q1:Are you a trading company or manufacturer?A1: We are a manufacturer more than 17 years.Q2:Can you help me solve a whole stamping line?A2: Yes, please provide the product drawings, and then we'll give you a best project.

Q3:How long does the general lead time take?A3:All machines need to be arranged for production, which shall be determined to the situation at that time.

You may also like

Send inquiry

Send now