Milk Chocolate Coated Malt Balls Casting Moulding Machine

Chocolate Chip Depositor Chocolate Making Machine Main Introducion: 1.The chocolate drops depositing machine is used for;

Basic Info

| Model NO. | MG-QDJ800 |

| Power Source | Electric |

| Process | Thermal Processing |

| Automatic Grade | Automatic |

| Application | Chocolate |

| Customized | Customized |

| Condition | New |

| Width of Conveyer Belt | 400mm |

| Temperature in Cooling Tunnel | 0-10°c |

| Weight of Machine | 2400kg |

| Transport Package | Strong Wooden Cases |

| Specification | CE |

| Trademark | SIGNUM |

| Origin | China |

| HS Code | 84383000 |

| Production Capacity | 100sets/Year |

Product Description

Chocolate Chip Depositor Chocolate Making MachineMain Introducion:

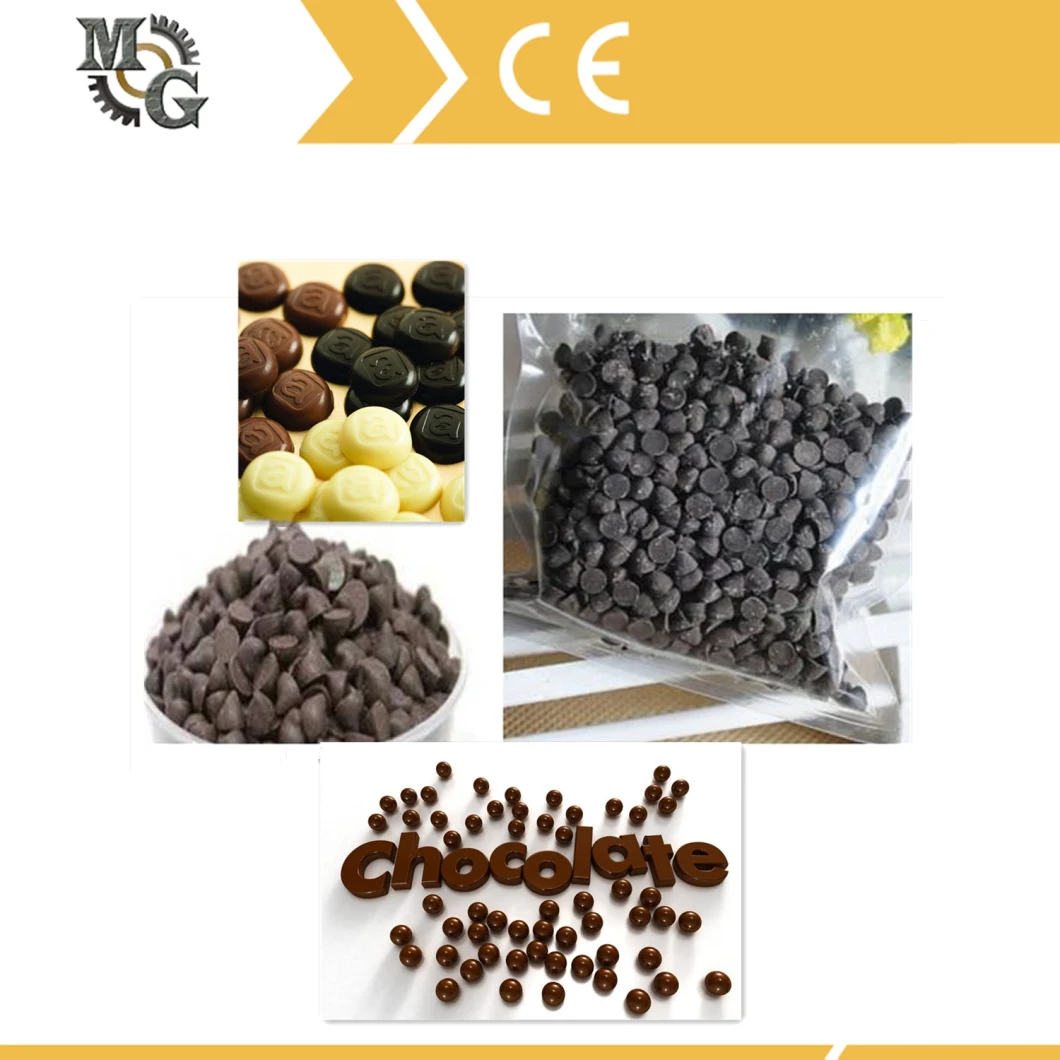

1.The chocolate drops depositing machine is used for producing particle chocolate chips. It can produce chocolate chips with a tail on top (like water drops), in the same machine it can also produce chocolate chips without a tail on top (like button).

2.The size and weight of chocolate chips can be adjustable in machine as per your requirement.

3.The chocolate chips depositing machine comprise of depositor and cooling tunnel. It is controlled by PLC system.

4. Real chocolate and compound chocolate are both workable to make in this machine.

Main parameter:

| Width of conveyer belt | 400mm |

| Speed of conveyer belt | 0-3m/minute |

| Depositing speed | About 15 times/minute |

| Diameter of chocolate chips | 4-12mm adjustable |

| Weight of chocolate chips | 0.1-2g adjustable |

| Capacity of 1.9g chocolate chips | 40kg/hour |

| Power of compressor | 6HP |

| Temperature in cooling tunnel | 0-10°C |

| Material of machine | All stainless ste |

| Weight of machine | 2400kg |

| Size of Machine | 13000x800x1600 mm |

Chocolate chips depositing machine with 600mm width conveyer belt (model: MGQDJ600), 800mm width conveyer belt (model: MGQDJ800), 1000mm width conveyer belt (model: MGQDJ1000) and 1200mm width conveyer belt (model: MGQDJ1200) are available as below:

| Model | MGQDJ600 | MGQDJ800 | MGQDJ1000 | MGQDJ1200 | |

| Width of conveyer belt (mm) | 600mm | 800mm | 1000mm | 1200mm | |

| Speed of conveyer belt (m/minute) | 0 - 3 | 0 - 3 | 0 - 3 | 0 - 3 | |

| Depositing speed (times/minute) | About 15 | About 15 | About 15 | About 15 | |

| Capacity (kg/hour) | If 0.1g chips | 60 kg/hour | 80 kg/hour | 100 kg/hour | 120 kg/hour |

| If 1g chips | 150 kg/hour | 200kg/hour | 250 kg/hour | 300kg/hour | |

| Power of Compressor | 5HP | 8HP | 8HP | 8HP | |

| Brand of Compressor | COPELAND | COPELAND | COPELAND | COPELAND | |

| Temperature in Cooling Tunnel | 5 - 10°C | 5 - 10°C | 5 - 10°C | 5 - 10°C | |

| Power of machine (kw) | 12 | 18 | 18 | 18 | |

| Weight of Machine (kg) | 2500 | 2600 | 3000 | 3200 | |

| Size of Machine (L×W×H, mm) | 12000×1050×1600 | 12000×1250×1600 | 12000×1450×1600 | 12000×1650×1600 | |

Packaging & Shipping

1. Strong seaworthy wooden package.

2. Protection against humidity.

3. Skilled capability of delivery to your country.

Guarantee & After-Sales Services

1. One-year guarantee period for complete machine.

2. Free charge of accessories within guarantee period excluding false operation.

3. Free charge of layout design, instruction with details, installation guide and local team training.

4. Experienced engineer is available to set up the machines upon request.

5. 24 hours technical support service by email and mobile.

You may also like

Send inquiry

Send now