Tumble Belt Blast Machine Automatic Sand Blasting Machine

Basic Info

| Model NO. | KF-A40 |

| Kind | Dry Sandblaster |

| Condition | New |

| Certification | CE |

| Customized | Customized |

| Name | Tumle Belt Blast Machine Automatic Sand Blasting M |

| Item | Tumle Belt Automatic Sand Blasting M |

| Type | Automatic Tumble Belt Sandblasting |

| Blasting Gun Qty | 4PCS, as Request |

| Use | Cleaning, Finishing |

| Voltage | 380V 50Hz |

| Productivity | 0.3-0.5 T/H |

| Load Capacity | 1-100kgs |

| Rolling Motor Power | 1.5kw |

| Dust Collection Motor Power | 2.2kw |

| Delivery | 15 Days |

| Transport Package | Wooden Case |

| Specification | L600*W500*H500 (mm) |

| Trademark | Kafan |

| Origin | China |

| Production Capacity | 100set/Month |

Product Description

Tumle Belt Blast Machine Automatic Sand Blasting MachineTumble belt automatic sandblasting machine are ideal for processing in small and medium sized parts in batches, as well as relatively heavy, complex-shaped parts that would be hard to handle in a traditional blasting cabinet.

The tumble belt sand blasting machines are used for surface cleaning of cast, pressed, heat treated, forged, etc. products without sharp corners and suitable for rounding. Ability to sandblast small and medium sized parts is the significant advantage.

Automatic Tumble Belt Sand Blasting Machine Features

1. Long life, wear-resistant rubber belt with a loading capacity of 100kgs.

2. Blasting guns are composed of boron carbide nozzles, which is the most durable materials in the market.

3. Easy-to-use electric control to adjust blasting pressures, belt tumbling speed, and blasting cycle time, etc.

4. Blast media is continuously separated from dust by a cyclone device, returning only pure blast media in good shape back to the blast nozzles for optimal results.

5. Configured a pulse filter cartridge for dust removal system, features high removal efficiency and requires easy installation and maintenance.

6. The blast guns quanity, swing speed, rubber belt size, all can be tailored to the customers specifications to address all process constraints and for optimal results and productivity.

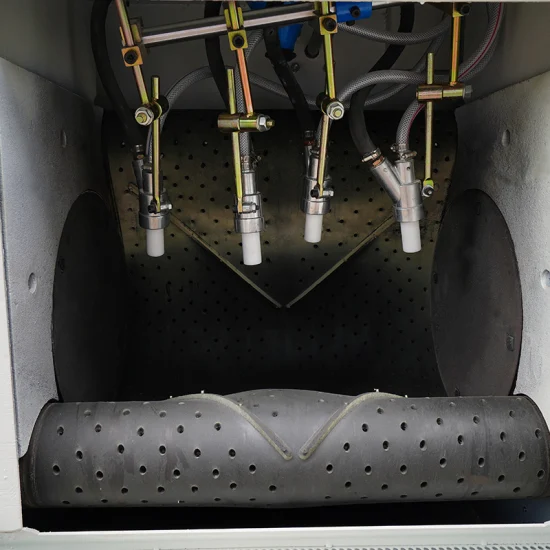

The working principle:Simply load parts on the rubber belt and set the timer, then return later to unload perfectly cleaned or finished parts. Parts tumble on a thick, perforated rubber belt, a group of blast guns uniformly blast medias to all exposed surfaces to deliver a consistent finish automatically. Nozzles are mounted on an oscillating blast gun to ensure maximum coverage of all parts.Tumble Belt Sandblasting Machine Specifications

| Model | KF-A40 |

Working cabinet: | L600*W500*H500 (mm) |

Cabinet outsize: | L800*W650*H2720 (mm) |

Dust collector dimensions: | L800*W800*H2100mm |

Productivity: | 0.3-0.5 T/H |

Load capacity: | ≤100KGS |

Rolling motor power: | 1.5KW |

Dust collection motor power: | 2.2KW |

Automatic blasting gun: | 4pcs Aluminium alloy blasting guns, with 4pcs boron carbide nozzles, dia 8mm. |

Voltage: | 380V 50HZ |

Note: We provide Custom Design service. The size of working chamber, the blast gun quantity can be made as customer's requirements.

The machine type can be chosen from tumble type, roller type, conveyor type etc.

Kafan Company

Kafan provides professional surface treatment solutions for industries like shipping, steel structure, container, automobile accessory, various hardware, stone carving, plastics crystals, glass, ceramics rinding and many others.

Our products can be divided into two main parts, sandblasting equipment and mass finishing machines.

Sandblasting equipment including: manual sandblasting machine, suction sand blast cabinet, pressure blasting machine, wet abrasive blasting equipment, portable blaster pot, automatic conveyor blast system, tumbler blaster, rotary table blast machine, crawl blast machine, blasting parts and abrasives.

Mass finishing system including: vibratory polishing & deburring bowl, vibratory bowl with separator, centrifugal barrel tumbling machine, centrifugal disc finishing system, mass finishing media.

Standard Production Models, Customized Design Service, Before-order Technical Support, Engineer Oversea Installing & Training, Free Sample Testing, 24hour On-line Service, ODM, OEM

Get a quote now!