Wheel Powder Coating and Sand Blasting Machine System

Basic Info

| Model NO. | KF-1212FTA with Powder Coating Equipment |

| Kind | Dry Sandblaster |

| Condition | New |

| Certification | CE |

| Customized | Customized |

| Item | Sandblasting and Powder Coating System |

| Type | Manual Sandblaster |

| Use | Cleaning, Finishing, Powder Coating |

| Delivery | 20 Days |

| Sandblaster Working Size (L*W*H) | 1200*1200*800 mm |

| Sandblaster Dimension (L*W*H) | 1620*1250*2000 mm |

| Sandblaster Loading | Max. 200kgs |

| Spray Booth Overall Dimensions | Width1600*Depth2000*Heght2250mm |

| Curing Oven Working Dimensio | Width1600 X Height1800 X Depth1400 mm |

| Power | 110V/220V/380V/450V, 50-60Hz |

| Circulation/Air Flow | Vertical, Variable Through H |

| Dust Removal Method | Cartridge Filter Type |

| Air Source Requirements | Pressure 7 Bar |

| Required Flow | 0.8-1.2 M3/Min |

| Body Material | Cold-Rolled Plate |

| Transport Package | Wooden Case |

| Trademark | Kafan |

| Origin | China |

| Production Capacity | 100set/Month |

Product Description

Wheel Powder Coating and Sand Blasting Machine SystemThis manual powder coating system include sandblasting machine, powder coating booth, powder curing ovens and powder spray guns, good option for DIY coating wheels or other small to medium sized workpieces.

This sandblasting and powder coating package offers the flexibility to remove many types of workpiece surface imperfection, including burrs, rust, and paint removal resulting in a brightly polished matte type finish.

Kafan Sandblasting Cabinet Machine Features

Turntable Type Sandblasting Cabinet is specially applicable for surface treatment of cyclinder shape, irregular-shaped or heavy-weight products, like mold, statue, motor, car wheells, etc, which significantly reduce efforts and increase the working efficiency. Users handble the parts through a manual blast gun at the same time rotate the turntable, thus all sides and corners can be easily cleaned.

Specifications of Alloy Wheel Sand Blasting Machine

| Model | KF-1212FTA |

Overall Dimension | Length1200*Width1680*Height1840mm |

Work Chamber | Length1200*Width1200*Height800mm |

| Turntable | Diameter 800mm |

| Loading | Max. 200kgs |

Door Size | W830xH770mm |

Power Supply | 110V/220V, 50-60Hz (customized) |

| Motor Power | 0.75kw |

| Lighting | 18w Fluorescent |

| Blasting Gun | 1 piece with boron carbide nozzle |

| Compressed Air | 5-8 bar(kg/cm2) |

| Flow | 0.5-1.2m3/min |

1. The advanced DVC technology allows you to precisely control crucial paramters such as high voltage, spraying current and powder outpur, achieving perfect and repeatable coating results.

2. Three pre-set application programs stand for flat parts, profiles, re-coating applications, suitable for beginners. Allows specialists to store 20 personalized programs for different parts and jobs.

4. 100kv manual spray guns always maintain high transfer efficiency even after long time working.

5. Box feed type suitas for quick color change demands.

COLO-1517 Manual Powder Coating Spray Booth

1. A high-performance fan efficiently circulate air with low noise and less energy.

2. 0.1 Micron high-precision filters ensures only particle-free air discharged to workshop and increase powder recovery rate.

3. Powder-coated steel constructed booth is corrosion resistant for longer service life.

4. A removable powder hopper at booth bottom simplifies the utilization of recovery powders

6. A user-friendly PLC panel integrates all functions, such turning on / off fans, setting pulse-jetting time and interval, light on/off, emergency stop etc.

| Model | COLO-S-1517 |

| Operating Dimensions | Width1500*Depth1000*Heght1700mm |

| Overall Dimensions | Width1600*Depth2000*Heght2250mm |

| Weight | 480kg |

| Power Supply | 220V/380V, 3Phase, 50-60HZ |

| Fan Power | 2.2kw |

| Filter Count | 3 pcs, Quick-release Type |

| Filter Material | Polyester |

| Filter Cleaning | Pneumatic |

| Air Consumption | 4000m^3/h |

COLO-1864 Electric Powder Coating Curing Oven

COLO-1864 powder coating oven is simple and efficient for powder curing process, whose electric heating method provides a quick raise to required temperature with using less energy as well as keeps the environment clean.

It is the most popular model applying to batch heating jobs for small and medium sized parts, such as alloy wheels, bike frames, motorcycle parts, etc.

| Model | COLO-1864 |

| Working dimensions | Width1600 x Height1800 x Depth1400 mm |

| Overall dimensions | Width1900 x Height2200 x Depth1700 mm |

| Power supply electric | 18kw |

| Voltage | 380V/220V (Custom Voltage Available) |

| Frequency | 50-60hz |

| Warm-up time | 15-30 min. (180° C) |

| Temperature stability | < ± 3-5°C |

| Temperature max | 250° C |

| Ventilation performance | 805-1677m3/h |

| Motor power | 0.75kw |

| Circulation/ Air flowVertical | Variable through holes on the walls |

| Transportation | Trolley |

| Warranty | 12 months |

Kafan Surface Finishing-Sandblaster and Powder Coating System

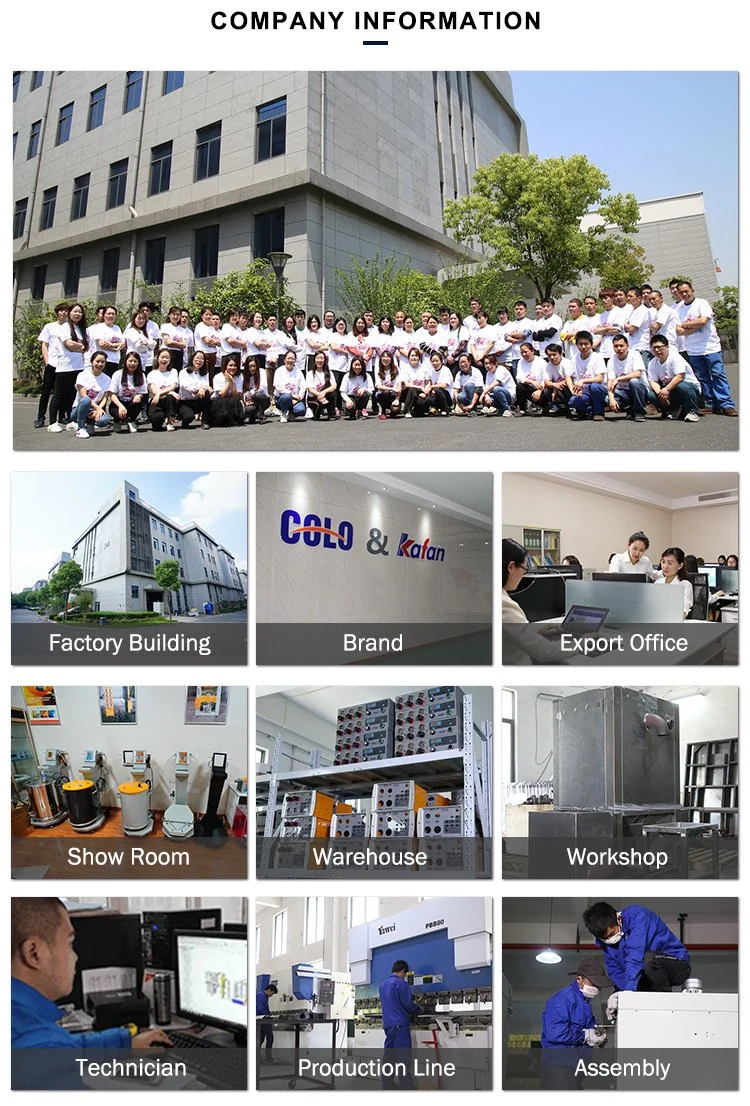

Kafan is your first choice of surface finishing equipment manufacturer, which solve the difficulty, expense and time cost that you face in pursuing a brilliant surface effect, such as cleaning, deburring, polishing, descaling, decorating, refurbishing.Sand Blasting Cabinet Produced by Kafan Company

Kafan is a professional manufactuer of surface finishing machinery. We have worked on worldwide market for 10 years, because of the superior technology, quality, service. We exported into more than 100 countries, established long term business with distributer in US, Mexico, Russia, Poland, UK, Germany ect..

Sandblasting equipment including: manual sandblasting machine, suction sand blast cabinet, pressure blasting machine, wet abrasive blasting equipment, portable blaster pot, automatic conveyor blast system, tumbler blaster, rotary table blast machine, crawl blast machine, blasting parts and abrasives.

Mass finishing system including: vibratory polishing & deburring bowl, vibratory bowl with separator, centrifugal barrel tumbling machine, centrifugal disc finishing system, mass finishing media.

Standard Production Models, Customized Design Service, Before-order Technical Support, Engineer Oversea Installing & Training, Free Sample Testing, 24hour On-line Service, ODM, OEM

Get a quote now!